New spray dryer boosts efficiency and cost savings for industry

A new spray dryer developed by chemical engineers at the University of Sydney could offer food and medicine businesses a more efficient and cost-effective method for producing their goods.

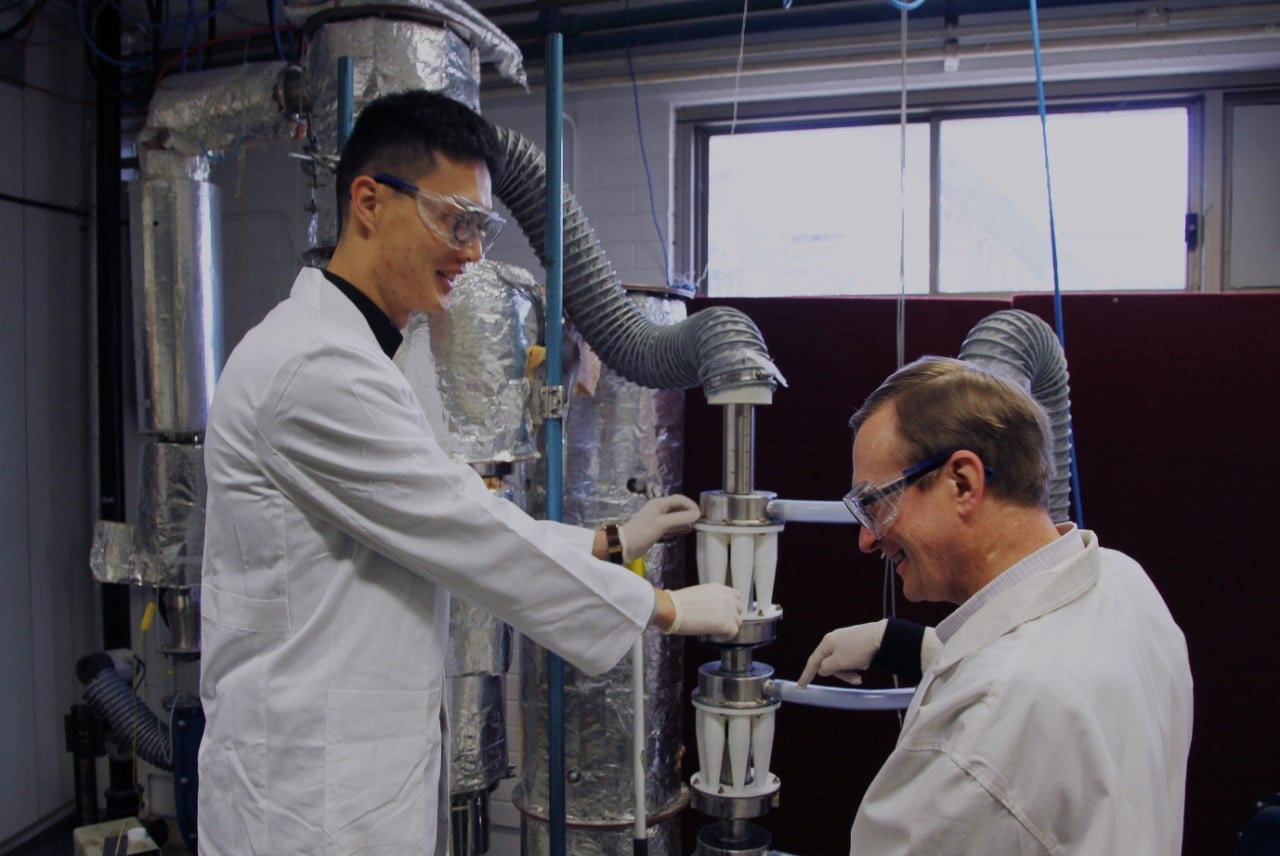

Professor Timothy Langrish and PhD candidate Harry Huang work on the new spray dryer.

Spray dryers use hot gas to convert liquid to powders and are widely used by industry for the creation of dry foods – including powdered milk, instant coffee and cereal – and pharmaceutical products, including antibiotics and some medications.

The team of researchers in the ARC Training Centre for the Australian Food Processing Industry in the 21st Century at the University of Sydney have developed and tested a new pilot-scale spray drying system that is particularly well suited for materials with heat-sensitive compounds, such as foods, pharmaceuticals, waste and bioactives (non-essential compounds, such as caffeine and fatty acids).

The new design also has advantages for product purity and recovery in other applications, such as detergent manufacturing.

“The benefits for industry will include both cost savings and quality improvements for foods and pharmaceuticals to give health gains,” said Professor Timothy Langrish, who is leading the research with his PhD candidate Harry Huang.

“We have only tested the new spray dryer with salt so far, but all foods and pharmaceuticals will potentially benefit from this new design. Many waste products will also be treatable in ways that current designs cannot do.”

The new system also overcomes one of the major issues plaguing spray dryers today – the settling of particles and sediment onto the inner surface of the dryer.

“The new design features of this spray dryer have created a stable air flow, which reduces the likelihood of particles colliding with the wall, thereby reducing the amount of deposition and improving product recovery,” said Professor Langrish.

Tests of the new system showed a low amount of wall deposition, with less than five percent of solid materials remaining in the drying chamber. This result is promising in comparison to more than 30 percent wall deposition in most standard spray dryer designs.

“This outcome means almost all of the dried particles can be recovered from the system without being exposed to high temperatures for a long period of time,” said Mr Huang.

“This is particularly important for products such as foods, pharmaceuticals and bioactives, as the short times reduce the likelihood of degradation of heat-sensitive compounds.”

Professor Langrish said the next step was to develop the system further to dry materials at a higher capacity. The specific design feature which reduces pressure fluctuations is also currently being patented.

This system is intended to be part of an Advanced Food Engineering Pilot Plant that will demonstrate and develop leading-edge food products and processes, along with other cutting-edge technologies, processes and products developed by the ARC Training Centre for the Australian Food Processing Industry in the 21st Century.