New "designer" titanium alloys made using 3D printing

The research, published in Nature, could help extend the applications of titanium alloys, improve sustainability and drive innovative materials technologies.

Titanium and titanium alloys are essential for a wide range of technologies. The research holds promise for a new class of more sustainable high-performance titanium alloys for applications in aerospace, biomedical, and chemical engineering, as well as defence, space and the clean energy transition.

The research was led by the University of Sydney and RMIT in collaboration with Melbourne company Hexagon Manufacturing Intelligence.

Co-lead researcher, University of Sydney Pro-Vice-Chancellor (Research Infrastructure) Professor Simon Ringer said: “This research delivers a new titanium alloy system capable of a wide and tunable range of mechanical properties, high manufacturability, enormous potential for emissions reduction and insights for materials design in kindred systems.”

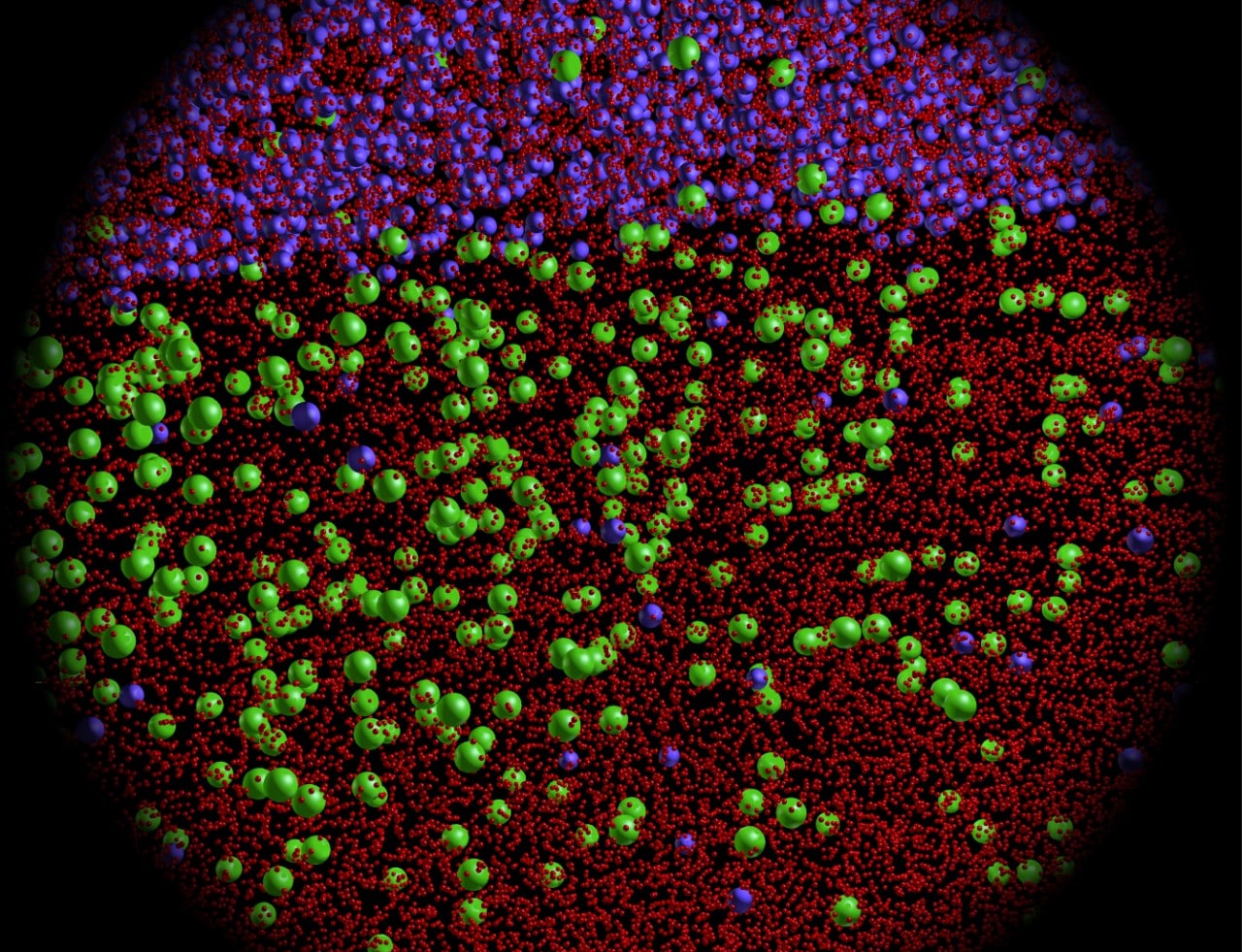

The new materials belong to an alloy class that has long been the backbone of the titanium industry. They consist of a mixture of two forms of titanium crystals, called alpha-titanium phase and beta-titanium phase, each corresponding to a specific arrangement of atoms.

While titanium alloys have traditionally been produced by adding aluminium and titanium, the researchers investigated the use of oxygen and iron – abundant and inexpensive elements that can act as powerful stabilisers and strengtheners of alpha- and beta-titanium phases.

“The critical enabler is the unique distribution of oxygen and iron atoms within and between the alpha-titanium and beta-titanium phases,” said Professor Ringer, an expert in materials science and engineering in the School of Aerospace, Mechanical and Mechatronic Engineering.

Pro-Vice-Chancellor (Research Infrastructure) Professor Simon Ringer. Credit: Louise Cooper, University of Sydney.

“We've engineered a nanoscale gradient of oxygen in the alpha-titanium phase, featuring high-oxygen segments that are strong, and low-oxygen segments that are ductile (retaining its strength after being moulded into a narrow thread) allowing us to exert control over the local atomic bonding and so mitigate the potential for embrittlement.”

Lead researcher Distinguished Professor Ma Qian from RMIT said the team embedded circular economy thinking in their design, creating great promise for producing their new titanium alloys from industrial waste and low-grade materials.

“Reusing waste and low-quality materials has the potential to add economic value and reduce the high carbon footprint of the titanium industry,” said Professor Qian from RMIT’s Centre for Additive Manufacturing in the School of Engineering.

According to the researchers, two challenges have hindered the development of strong and ductile alpha-beta titanium-oxygen-iron alloys through conventional manufacturing processes.

“One challenge is that oxygen – described colloquially as ‘the kryptonite to titanium’ – can make titanium brittle, and the other is that adding iron could lead to serious defects in the form of large patches of beta-titanium,” said Professor Ma Qian.

The team used Laser Directed Energy Deposition (L-DED), a 3D printing process suitable for making large, complex parts, to print their alloys from metal powder, developing a unique microstructure to rival commercial alloys.

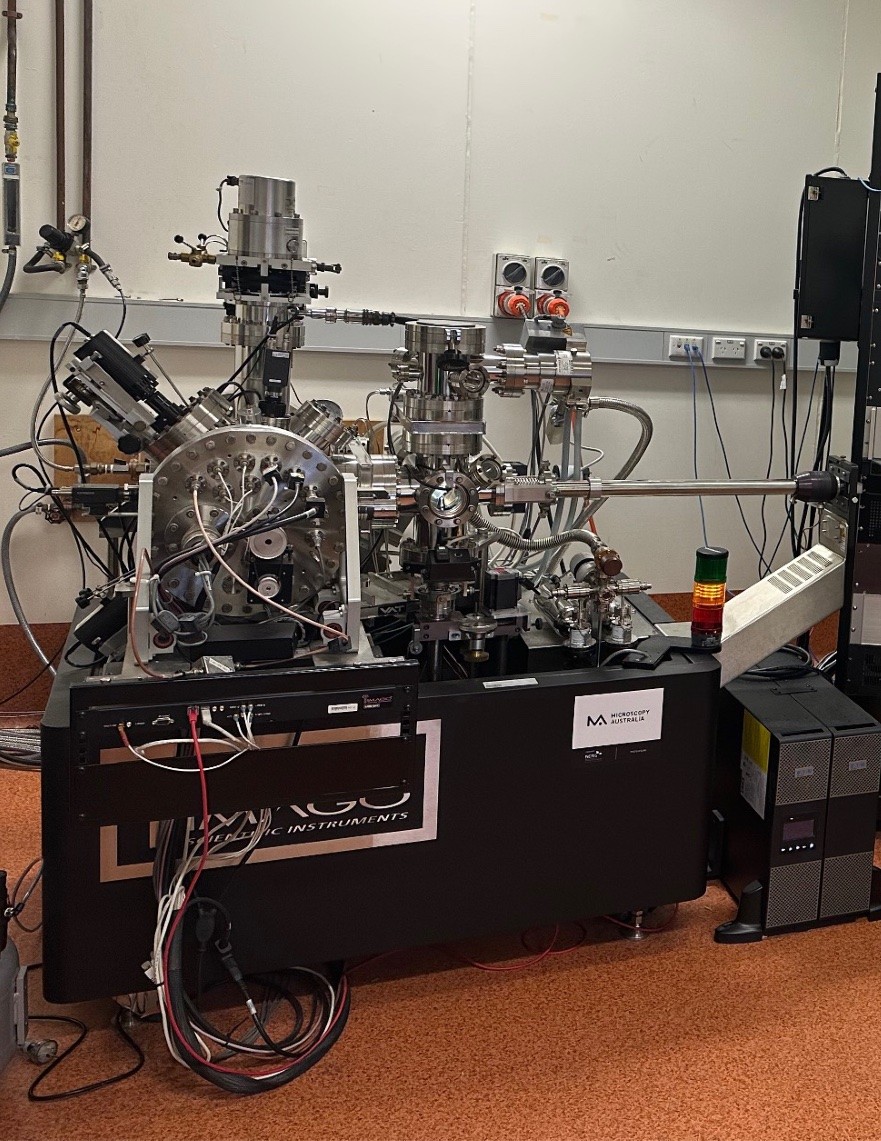

The Sydney Microscopy and Microanalysis atom probe that was used in the research. Credit: University of Sydney Pro-Vice-Chancellor (Research Infrastructure) Professor Simon Ringer.

Lead author Dr Tingting Song, RMIT Vice-Chancellor’s Research Fellow, said: "3D printing offers a fundamentally different way of making novel alloys and has distinct advantages over traditional approaches. There’s a potential opportunity for industry to reuse waste sponge titanium-oxygen-iron alloy, ‘out-of-spec’ recycled high-oxygen titanium powders or titanium powders made from high-oxygen scrap titanium using our approach.”

Co-lead author Dr Zibin Chen*, who conducted the research at the University of Sydney and joined Hong Kong Polytechnic University in the later stages of the collaboration, said the research had broader implications: “Oxygen embrittlement is a major metallurgical challenge not only for titanium, but also for other important metals such as zirconium, niobium and molybdenum and their alloys. Our work may provide a template to mitigate these oxygen embrittlement issues through 3D printing and microstructure design.”

-in-front-of-the-laser-3d-printer-that-the-team-used-at-rmit-university_credit-rmit.jpg/_jcr_content/renditions/cq5dam.web.1280.1280.jpeg)

Professor Ringer's collaborators from RMIT: Dr Shenglu Lu, Alan Jones, Dr Tingting Song, Professor Ma Qian and Professor Milan Brandt (left to right) in front of the laser 3D printer that the team used at RMIT.

Professor Ringer said the team’s work benefited from sustained, targeted investment in research infrastructure from national and state governments and universities.

“In many ways, this work showcases the power of Australia's national collaborative research infrastructure strategy and sets the scene for extending this strategy into the realm of advanced manufacturing,” he said.

DISCLOSURE

The Australia Research Council (ARC) through the Discovery Program and the Training Centre in Surface Engineering for Advanced Materials (SEAM) funded and supported this research.

The team acknowledges support from the Australia–US Multidisciplinary University Research Initiative (AUSMURI) program supported by the Australian Government; the State Key Laboratories in Hong Kong from the Governmental Innovation and Technology Commission; and Hexagon Manufacturing Intelligence (Melbourne, Australia) for its Simufact DED solution used in the L-DED process design. The University of Sydney researchers acknowledge technical and scientific support for atom probe and electron microscopy experiments at Sydney Microscopy and Microanalysis (SMM). SMM is a foundational node of Microscopy Australia, the NCRIS supported national microscopy facility. *Dr Zibin Chen participated in the project while at the University of Sydney; after transferring to Hong Kong Polytechnic University his contribution to the final manuscript and a follow up experiment were completed with junior members of his new team.

The team’s research paper, ‘Strong and ductile titanium-oxygen-iron alloys by additive manufacturing’, is published in Nature (DOI: 10.1038/s41586-023-05952-6).