I Love Stainless Steel

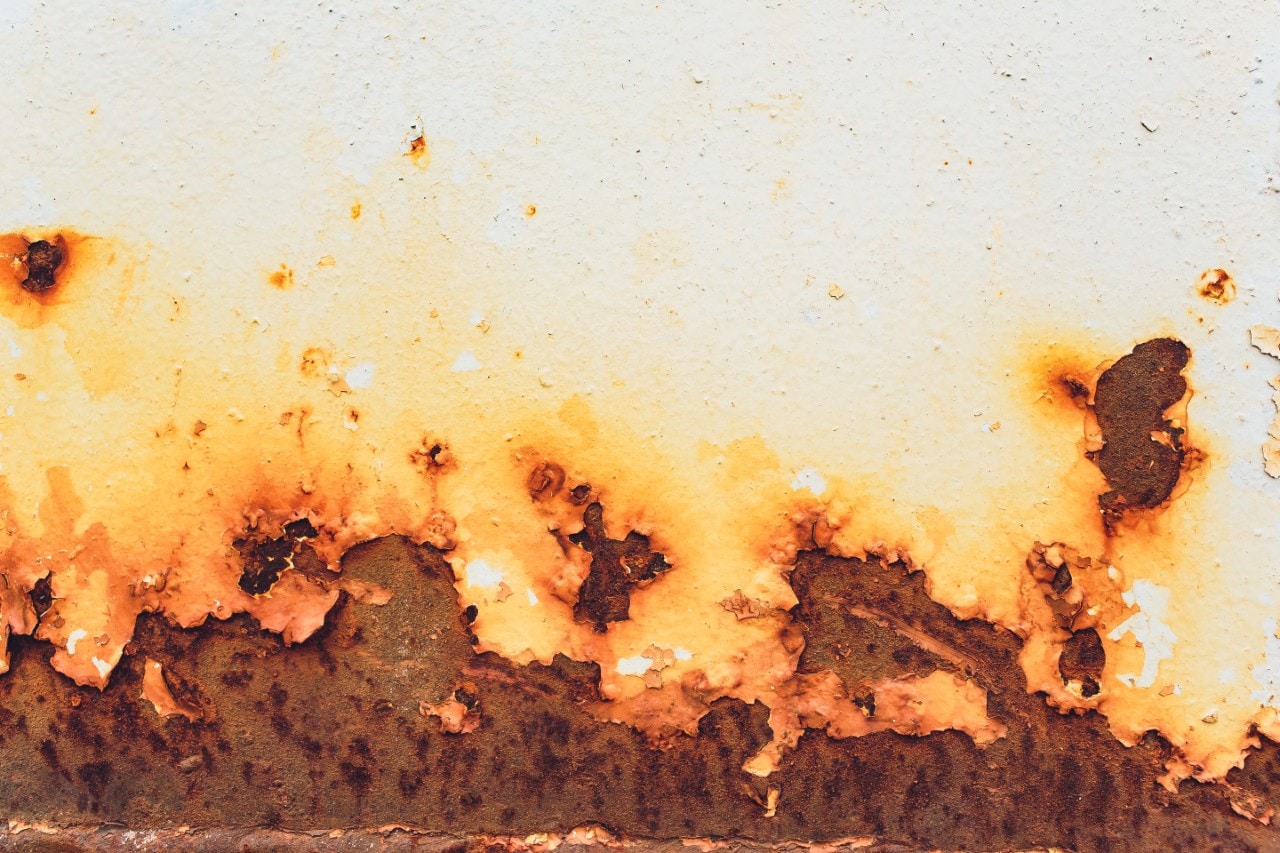

I would spin wire brushes on my electric drill onto the rust bubble in the car paint, until I got back to shiny clean steel. A tiny 3 mm barely-visible rust bubble could expand to a hole bigger than my fist – before I got clean metal edges. I would fill the cavity with fly screen and shovel-loads of “bog”, sand it back to follow the body shape, and finally colour match the paint.

Ever since those Bush Mechanic days, I have loved stainless steel – because it doesn’t rust like regular steel.

Rust forming on a white metal wall.

Back in 1821, the French metallurgist, Pierre Berthier, added chromium to iron to make the iron more resistant to corrosion. In 1872, John T Woods and John Clark from England patented a “Water Resistant” alloy – quite similar to today’s stainless steel. By the early 1900s various stainless steel alloys were used for a chrome-nickel hull for a ship, corrosion-resistant gun barrels and humble cutlery.

There are about 150 varieties of stainless steel, but only a dozen-or-two are in common use. Stainless steels can have different crystalline structures, can be magnetic or non-magnetic, and can have different degrees of corrosion resistance, and hardness. But in general, to be counted as a stainless steel, there has to be a minimum of 11% chromium by weight.

Now here’s the metallurgical truth. Stainless does “rust”. I use “rust” in the sense of an oxide coating on an underlying metal.

So, it DOES rust, but in a protective way. The rust of stainless is both very adherent (or sticky), and not porous.

To understand this more, let’s look at plain iron.

Iron can react with oxygen to create iron oxide. This rust spreads and is fragile.

First, this rust is very porous. Both water and oxygen quickly diffuse right through it to get at the pure iron metal underneath. Second, this rust doesn’t “stick” to the iron, and it flakes off very easily.

The cycle starts with iron rusting on its surface, then water and oxygen diffuse through that new rust. This rust flakes off, leaving behind a new iron surface. Next, that fresh iron rusts, and the process repeats until all the iron has turned into soft, porous flaked-off tiny rust fragments. (But if you look up “Pilling Bedworth Ratio”, you’ll see that my “explanation” is a vast simplification.)

But stainless steel is different – in both porosity and adhesion. Yes, it is mostly iron, but it also has at least 11% chromium. At the surface, the oxygen combines with the chromium, to create the shiny rust called chromium oxide. This rust is very different from iron oxide. First, chromium oxide is very non-porous – water and oxygen can’t get through it. Second, the chromium oxide rust is very tightly adherent – it sticks very firmly to the iron beneath it. So once this very thin shiny surface layer of chromium oxide rust forms – the reaction of rusting simply stops.

So stainless steel, depending on the added alloys and the local environment, does not rust to destruction. If that thin surface layer of chromium oxide “rust” is scratched, the chromium reacts with oxygen – and the rusting stops. So you can think of stainless steel as being self-repairing.

For me, the stainless car (the DeLorean, from Back to the Future) came too late.

Related articles

New hybrid agriculture model brings food and energy benefits

Combining traditional agricultural farming land with renewable energy technologies reap potential benefits.