Connect with us

Follow us on social media

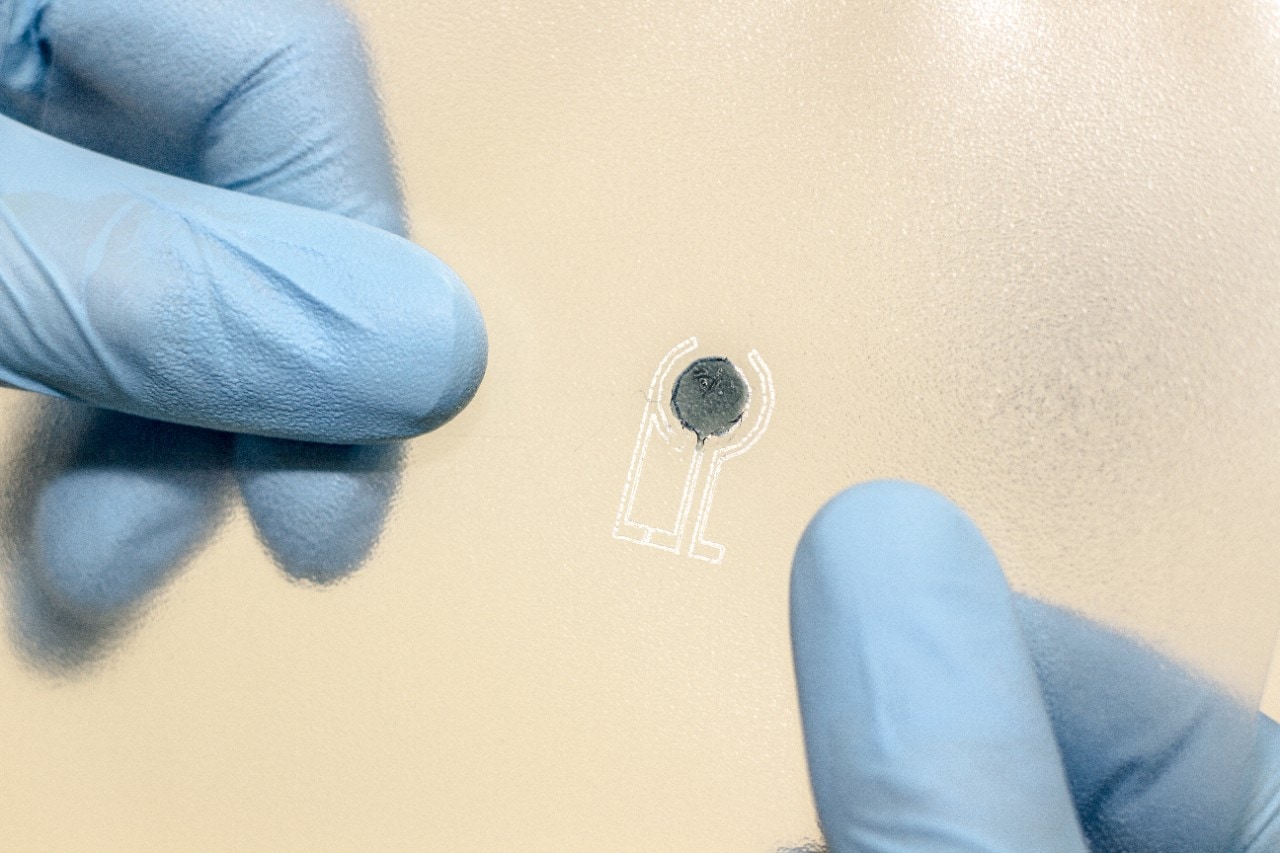

Printable food ink sensor developed by Dr Sina Naficy

We’ve all done it. Food perfectly fit for consumption is thrown away just a day past its ‘best before date’. We know that expiry dates and best before dates aren’t the best indicators of food spoilage, but can we engineer a better way to know when to scrap our food Chemical engineer Dr Sina Naficy is determined to find out.

Food waste is a major concern for both the environment and food security. According to the Love Food Hate Waste Tracking Survey (2015–2016), Australian households throw away an average of $1036 worth food per year. While there are several reasons for food waste, over purchasing–often leading to food spoilage–is a major factor.

Dr Sina Naficy from the School of Chemical and Biomolecular Engineering is searching for a solution through his research in ‘food sensor technology’. Food sensors refer to a range of technologies used to identify and monitor food characteristics such as temperature, defects and of course, spoilage.

Dr Naficy is investigating the design of printable ‘gas sensors’. The idea is to create a type of ink for food packaging that can detect the gases generated by bacteria in packaged food. Certain gases such as ammonia, hydrogen sulphide, nitrogen dioxide and carbon dioxide are crucial indicators of the quality of the food. By creating food packaging that can detect these gases, we can start to gain an accurate indication of food expiration.

“Current gas sensors are rigid, bulky and expensive, and at present can’t be incorporated in food packaging. By designing flexible conductive inks to print electronic circuits on the paper using standard inkjet printers, we will provide a practical, cost-effective solution for manufacturers”, says Dr Naficy.

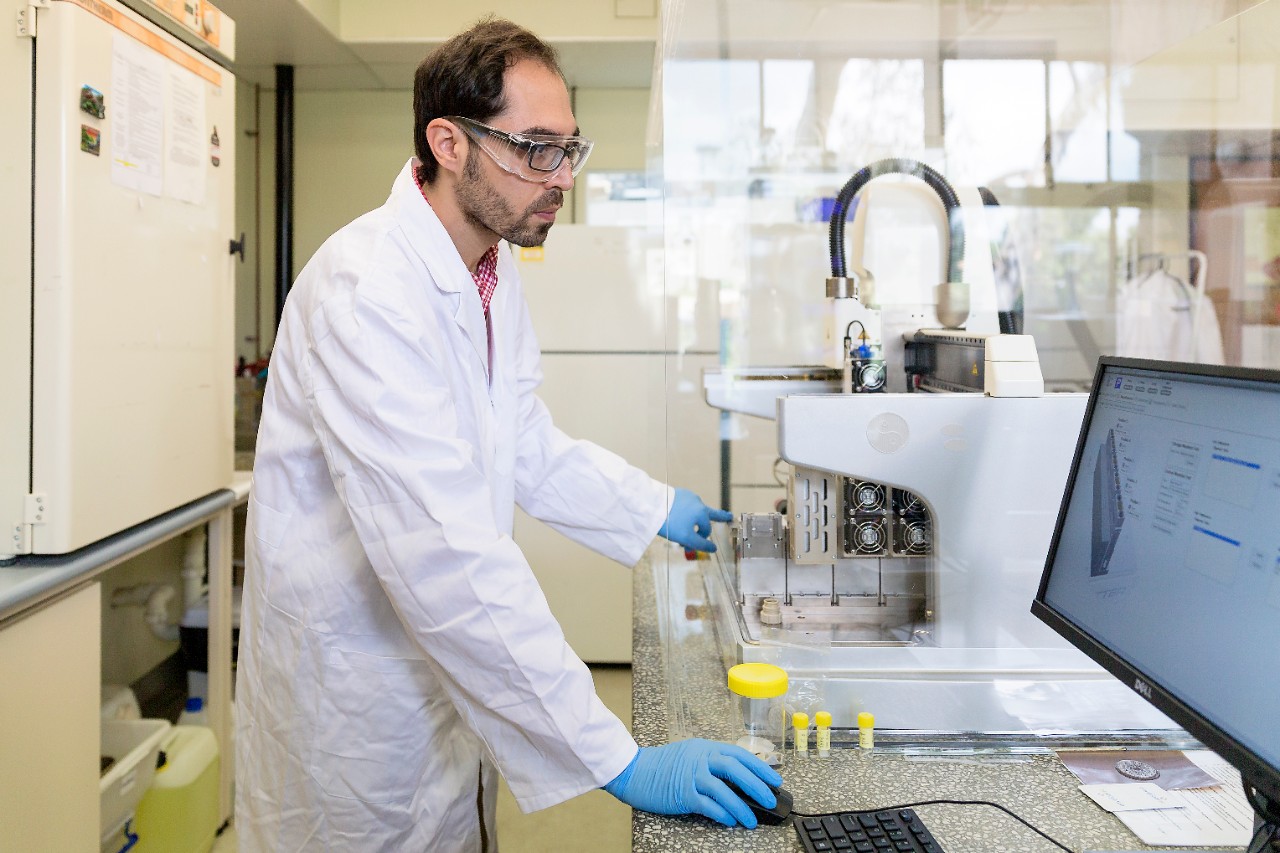

Dr Sina Naficy 3D printing novel food ink sensors in laboratory.

So how will these sensors work? The ink will be conductive, allowing it to transmit a signal to a device that captures the data and gives a precise reading of certain gas levels. This technology could provide food suppliers with invaluable data, informing essential decisions from storage conditions to purchasing behaviour and food safety compliance. All these factors, if executed properly, could lead to massive reductions in food waste.

The project, which was an initiative undertaken by the ARC Training Centre for the Australian Food Processing Industry in the 21st Century, has received an Endeavour Scholarship which will take Dr Naficy to the Centre for Plastic Electronics at the Imperial College London, allowing him to expand on the work on the sensor design, optimisation and prototyping with international collaborators. Dr Naficy has recently joined The University of Sydney’s Centre for Excellence in Advanced Food Enginomics. The centre aims to find innovative solutions in food products, processes and supply chains to promote human wellbeing. Dr Naficy’s exemplary work marks a momentous step towards this goal.