Scientists manufacture 'living blood vessel'

An international consortium of researchers led by the University of Sydney, has developed technology to enable the manufacturing of materials that mimic the structure of living blood vessels, with significant implications for the future of surgery.

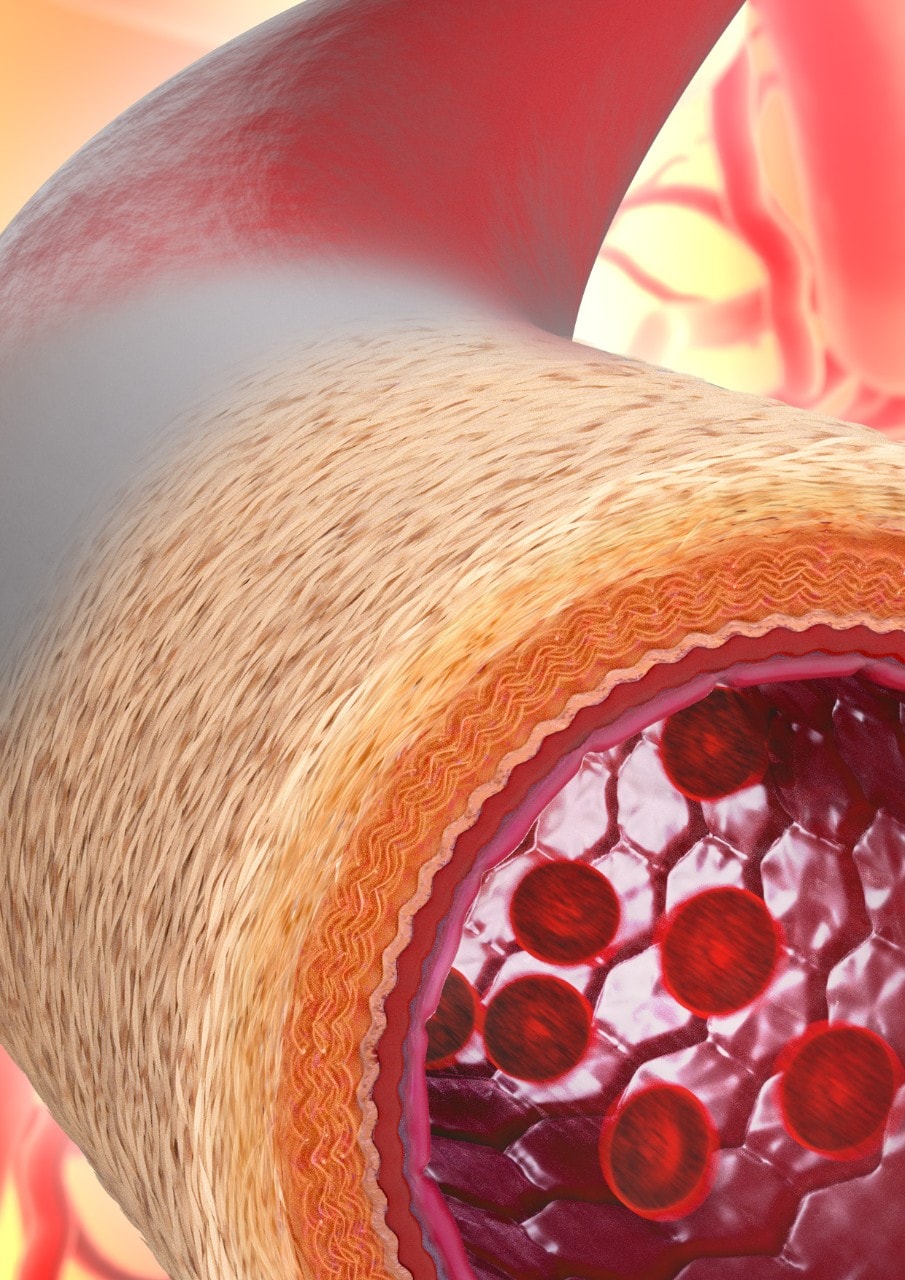

Artist's representation of the 'living blood vessel'. Credit: Designed by Ziyu Wang and illustrated by Ella Maru Studio

Preclinical testing found that following transplantation of the manufactured blood vessel into mice, the body accepted the material, with new cells and tissue growing in the right places – in essence transforming it into a ‘living blood vessel.

Senior author Professor Anthony Weiss from the Charles Perkins Centre said while others have tried to build blood vessels with various degrees of success before, this is the first time scientists have seen the vessels develop with such a high degree of similarity to the complex structure of naturally occurring blood vessels.

“Nature converts this manufactured tube over time to one that looks, behaves and functions like a real blood vessel,” said Professor Weiss.

“The technology’s ability to recreate the complex structure of biological tissues shows it has the potential to not only manufacture blood vessels to assist in surgery, but also sets the scene for the future creation of other synthetic tissues such as heart valves.”

Nature converts this manufactured tube over time to one that looks, behaves and functions like a real blood vessel

Close up of the structure of the material used to construct the 'living blood vessel'

Co-author Dr Christopher Breuer of the Center for Regenerative Medicine at Nationwide Children's Hospital and the Wexner Medical Center in Columbus, USA said he is excited about the potential of the research for children.

“Currently when kids suffer from an abnormal vessel, surgeons have no choice but to use synthetic vessels that function well for a short time but inevitably children need additional surgeries as they grow. This new technology provides the exciting foundation for the manufactured blood vessels that to continue to grow and develop over time.”

Lead author and bioengineer Dr Ziyu Wang from the University of Sydney’s Charles Perkins Centre pioneered the technology which was developed as part of his PhD. He built on earlier work by Dr Suzanne Mithieux, also at the Charles Perkins Centre.

The walls of natural blood vessels comprise a series of concentric rings of elastin (a protein that gives vessels elasticity and the ability to stretch)– like nesting dolls. That makes the rings elastic, which allows blood vessels to expand and contract with blood flow.

This new technology means that, for the first time, these important concentric elastin rings can develop naturally within the walls of implanted tubes.

Unlike current manufacturing processes for synthetic materials used for surgery, which can be lengthy, complex and expensive, this new manufacturing process is swift and well-defined.

“These synthetic vessels are elegant because they are manufactured from just two naturally occurring materials that are well-tolerated by the body,” said Dr Wang.

“Tropoelastin (the natural building block for elastin) is packaged in an elastic sheath which dissipates gradually and promotes the formation of highly organised, natural mimics of functioning blood vessels.”

The manufactured tube can also be safely stored in a sterile plastic bag until transplantation.

The study led by the University of Sydney’s Charles Perkins Centre and Faculty of Science is published in the international journal Advanced Materials.

Declaration: Ethics approval was obtained from the Sydney Local Health District, Australia and Nationwide Children’s Hospital, USA. Professor Anthony Weiss is the founding scientist of Elastagen Pty.Ltd., now sold to Allergan, Inc., an AbbVie company. The authors declare no other competing interests.