CO2MOF network

Our research team comes from disciplines ranging across theoretical chemistry, inorganic chemistry, mathematics and chemical engineering, and is drawn from seven institutions: The University of Sydney, The University of Melbourne, The University of New South Wales, The University of Adelaide, Monash University, CSIRO and ANSTO.

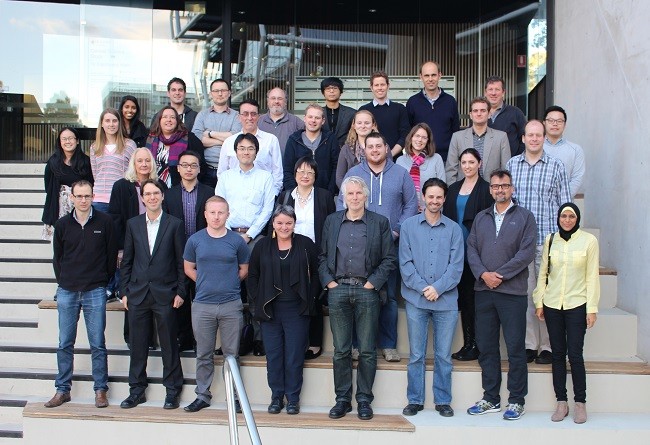

Our 2015 Annual Meeting

Our aims

We have identified four key challenges requiring research in order to capture and use CO2 on an industrial scale with MOF-based devices. Each of these will be the focus of one of our four research teams.

Our challenges are:

- the synthesis of novel MOF materials with exceptional CO2 separation capacities

- the development of MOF materials with catalytic abilities for CO2 conversion into usable products

- the scale-up and fabrication of membrane-based devices for integration of MOFs into industrial platforms

- the modelling, prediction and advanced characterisation of these new materials.

Our research

Four overlapping research teams have been assembled, each to focus on the specific scientific and technological issues of one of the four key challenges.

Materials for CO2 capture

Group leader: Professor Stuart Batten

With a few notable and instructive exceptions, most known MOFs do not perform well under industrially relevant conditions due to having moderate chemical and thermal stabilities. Drawing on our combined expertise in design, synthesis and characterisation, we are targeting the development of MOF materials for optimal CO2 separation under the high temperature and humidity conditions present in flue streams from industrial power stations.

Materials for CO2 utilisation

Group leader: Professor Alan Chaffee

CO2 is not only a powerful greenhouse gas, but a potential feedstock for many commercial chemicals. Over recent decades there has been much research on the conversion of CO2, but the possibility of using MOF materials as a catalyst for this purpose has been almost entirely unexplored. We are using existing research on CO2 conversion to evaluate and design MOF materials with catalytic abilities for CO2 conversion into usable products.

Scale up and device fabrication

Group leader: Professor Sandra Kentish

The integration of MOFs into practical CO2 capture processes requires substantial work on scale-up and fabrication of membrane-based devices. To date, studies on the viability of MOFs as CO2 capture materials under realistic flue stream conditions has received very limited attention. We are developing membranes and testing protocols to assess materials for CO2 separation and conversion.

Modelling, prediction and characterisation

Group leader: Associate Professor John Stride

Key to the development of MOF technologies is a fundamental understanding of their molecular structure and the way in which they interact with the CO2 molecule. This is being achieved through a unified characterisation approach in which high resolution structural information obtained through X-ray and neutron diffraction is combined with high level computational simulation.

Our database

We have compiled a database listing all the new materials published by CO2MOF collaborators, including structure and adsorption properties: CO2MOF Network Database

Background science

The last two decades have seen the explosive growth of a new class of materials. Variously known as metal-organic frameworks (MOFs) or porous coordination-polymers (PCPs), these microporous crystalline solids are composed of organic bridging ligands coordinated to metal-based units to form a three-dimensional extended network with uniform pore diameters typically in the range 3 to 50 Å. The intense current research effort towards industrial applications of MOFs in gas storage, separation and catalysis is attributed to their unique structural properties, including: robustness, high thermal and chemical stabilities, unprecedented internal surface areas (up to 10000 m2/g), high void volumes (up to 90%) and low densities (down to 0.21 g/cm3). The regular monodisperse nature of the crystalline array of micropores is a key feature that distinguishes these systems from other porous materials (for example polymers, mesoporous silicas and carbons, etc.). In addition, the ability to modulate systematically the pore dimensions and surface chemistry within MOFs, providing enormous structural and chemical diversity, is a feature that was previously largely absent in zeolite materials.

The high surface area-to-weight ratio of MOFs is such that they have enhanced capacities for CO2 capture at moderate pressures compared with zeolites. While zeolites possess higher storage capacities at pressures of less than 10 bar, it has been projected that their maximum capacities are limited to one third those of MOFs at pressures greater than 10 bar. The capacities of metal–organic frameworks up to high pressures scale with the amount of active area per unit weight: activated carbon has an active area of 400–1000 m2/g, zeolites of up to 1500 m2/g, and frameworks of 1500–4500 m2/g. The peak gravimetric adsorption for CO2 has been reported in frameworks with high surface areas and pore diameters of greater than 15 Å.

MOFs offer an unprecedented opportunity to target new materials with exceptional efficiencies for CO2 capture. Over the past decade a largely scattergun approach to materials discovery in this area has led to a broad array of highly porous materials displaying very impressive CO2 selectivities and capacities, with such properties in most cases requiring careful moderation of conditions (i.e., to prevent thermal decomposition and/or chemical decomposition with exposure for example to water vapour) but in a number of noteworthy cases occurring under industrially relevant conditions.

In contrast to the exploration of selective CO2 adsorption, the possibility of integrating multiple functionalities such as catalytic capabilities into MOFs that would enable the conversion of CO2 into viable commodities has been almost entirely unexplored. This is despite a wealth of literature spanning several decades on molecular approaches to CO2 conversion, and despite numerous chemical and technological advantages that are inherent in the use of solid-based approach to CO2 transformation. The opportunity therefore exists to couple the exciting CO2 utilisation found in molecular species with the molecular sieving selectivity, high capacity and improved exposure of reactive metal sites found in MOFs. For example, a molecular mercaptopyridyl copper species was recently reported as exhibiting rapid conversion of CO2 to oxalate, an important component in the deposition of complex metal oxide thin films for use in computer memory and solar cell electrodes. Incorporation of a similar reactive molecular unit into a MOF topology could deliver massive increases in the turnover rate of CO2 to oxalate, and very likely deliver this conversion from industrially relevant gas mixtures.

Carbon (dioxide) capture and storage (CCS) schemes embody a group of technologies for the capture of CO2 from large point sources such as power plants and natural gas wells, followed by compression, transport and permanent storage. Indeed, conventional technologies for large scale CO2 capture are already commercially available and are focused on postcombustion separation of CO2 from flue gases of power plants by the use of amine absorbers (‘scrubbers’) and cryogenic coolers. However, it is estimated that CO2 capture using conventional scrubbing increases the energy requirements of a plant by 25-35% owing to the dilute concentrations of CO2 (typically 10-15%) that are present at low pressures in the flue gas stream (at 1 atmosphere).

Clearly, the existing methods of capture are energy intensive and are not cost-effective for carbon emissions reduction. Indeed, one explanation for the slow deployment of fully-integrated commercial CCS schemes is the considerable cost of the capture phase, which represents approximately two thirds of the total cost for CCS. These considerations underscore the immense opportunities and incentives that exist for improved CO2 capture processes and materials.

A diverse range of promising methods and materials have been proposed as alternatives to conventional chemical absorption. These include the use of physical absorbents, membranes, cryogenic distillation, hydrate formation, chemical-looping combustion and adsorption on solids using pressure and/or temperature swing adsorption processes. One key challenge for gas separations materials is that the differences in properties between the gases that have to be separated are relatively small. Novel concepts for capture therefore require a molecular level of control that can take advantage of differences in the chemical reactivity of the gas molecules.

More detailed background information about CCS is published by the CRC for Greenhouse Gas Technologies.

t is possible that the carbon dioxide created by burning fossil fuels could be ‘recycled’ into fuels or other useful chemical commodities. There is a wealth of literature, spanning several decades, on conversion of CO2 using transition metal complex catalysts. While the catalytic reduction of CO2 is thermodynamically challenging, these reactions have been demonstrated on the laboratory scale.

However, there has been little progress in the development of solid-based catalysts for CO2 conversion, despite numerous chemical and technological advantages that are inherent in this approach. Furthermore, the possibility of integrating these catalytic capabilities into MOFs has been almost entirely unexplored. The opportunity therefore exists to couple the exciting CO2 utilisation found in molecular species with the molecular sieving selectivity, high capacity and improved exposure of reactive metal sites found in MOFs.

Key technical challenges include the creation of frameworks that are stable at moderately elevated temperatures and pressures in the absence of solvent, and which are catalytically active for CO2 conversion in both gas/solid and liquid phase reactions.

Institution |

Lead researchers |

Post-doctoral fellows |

|---|---|---|

| ANSTO |

Dr Josie Auckett |

|

| CSIRO |

Dr Nick Burke |

|

| Monash University | Dr Christian Vogt Dr Jamie Higgs |

|

The University of Adelaide |

||

| The University of Melbourne | Dr Shinji Kanehashi Dr Keith White |

|

| The University of New South Wales | Dr Fehmida Kanodarwala | |

The University of Sydney |

Professor Cameron Kepert (Director) Dr Deanna D'Alessandro |

Dr Florence Ragon Dr Tamara Church Dr Peter Southon (Project manager) |